pipe bursting

the pipe bursting process

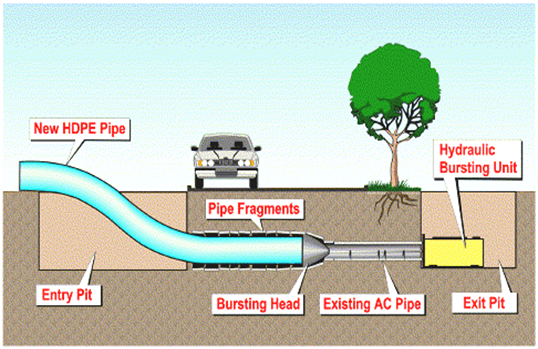

Pipe bursting is a process by which an existing pipe in need of replacement is fractured and displaced into the surrounding ground while simultaneously installing a new polyethylene pipe (PE or HDPE) of the same size or larger.

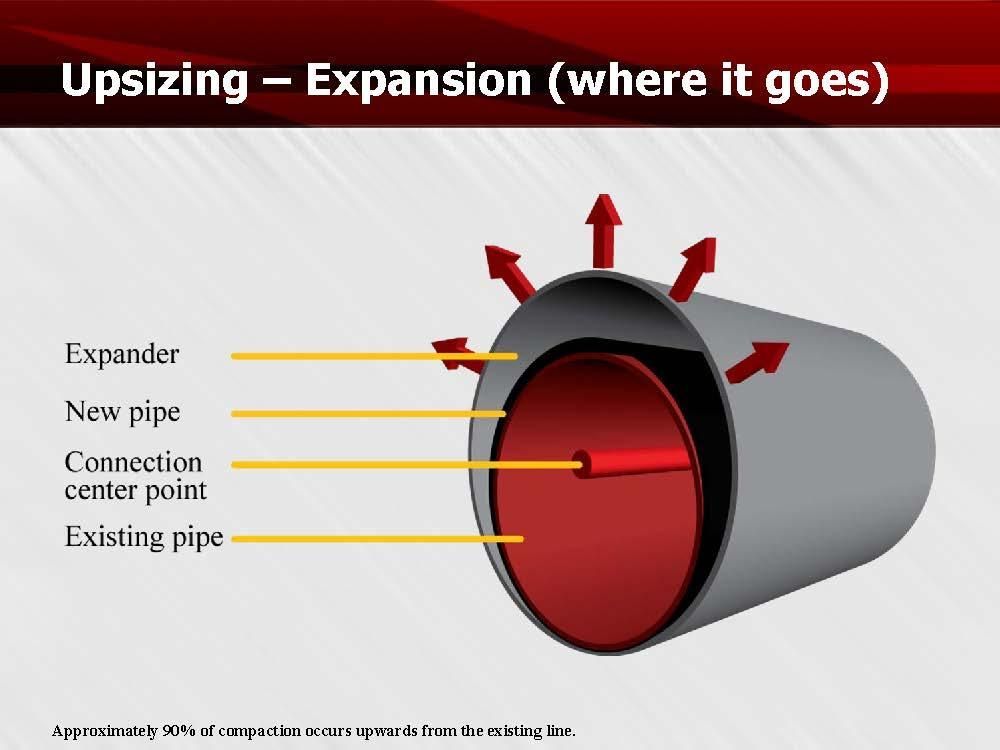

A portable static method of bursting is accomplished with a bursting head and hydraulic pulling device. The bursting head fractures the existing pipe and pushes the pieces into the existing bedding surrounding the line. The hydraulic pulling device provides traction for the bursting head, and permits navigating straight pipe sections as well as bends up to 45 degrees. The new pipe can be the same size or larger than the pipe it replaces (a practice known as upsizing). The steel bursting head is of a special design that grips the new pipe and protects the leading edge of the new pipe, while allowing navigation of the 45-degree bends.

Access pits are required at the beginning and end of the run of existing pipe that is to be replaced. The size of the entry pit for the new pipe is determined based on the pipe manufacturer's specified bend radius for the pipe being inserted. The cable of the hydraulic pulling device is fed through the existing pipe and attached to the nose of the bursting head.

The hydraulic pulling device pulls the bursting head through the existing line, breaking it into small pieces and pushing the pieces into the existing bedding. The bursting head is larger in diameter than the existing pipe and therefore creates an annular space that results in obstruction-free installation. The process is completed when the bursting head reaches the exit pit, a manhole or basement. The bursting head is then removed from the new PE pipe and the pipe is connected to the sewer main and house connection(s).

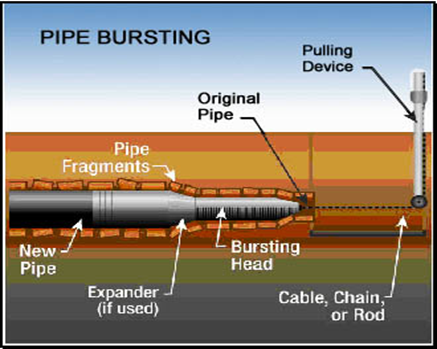

The pipe bursting head shall be designed and manufactured to force its way through existing pipe material by fragmenting the pipe and compressing the old pipe sections into the surrounding soil as it progresses.

The hydraulic pulling device shall generate sufficient force to pull the bursting head through the existing pipe, causing it to burst and compact the existing material into the surrounding ground. (See manufacturer's specifications for the size of bursting head to be used for each diameter of pipe, as well as requirements for upsizing.) The pipe bursting head shall be pulled through the sewer lateral by a hydraulic pulling device located in the exit pit at the opposite end of the lateral. The Bursting head shall pull the polyethylene pipe with it as it moves forward. The bursting head shall be designed so that it can be disconnected from the new pipe and retrieved from the exit pit or manhole.

The bursting head shall have a larger external diameter than the existing lateral, causing the pipe material to fracture while expanding the surrounding ground. This action shall not only break the pipe but also create a void through which the bursting head can pull in the new polyethylene pipe. The bursting head shall be designed so as to securely grip the PE pipe without need for fasteners or special tools.

The bursting head shall be pulled through the existing pipe by the hydraulic pulling device. The cable of the hydraulic pulling device shall be attached to the front of the bursting head. The hydraulic pulling device must pull the bursting head with sufficient force to burst the existing pipe and provide for expansion of the surrounding ground.